Solar Modules

In photovoltaic (solar) module light energy converts into electricity. A photovoltaic module is the basic element of each photovoltaic system. It consists of many jointly connected solar cells. According to the solar cell technology we distinguish monocrystalline, polycrystalline and amorphous solar modules. Detailed description on solar cell technologies you will find in the technologies section. Most commercial crystalline modules consist of 36 or of 72 cells. Solar cells are connected and placed between a tedlar plate on the bottom and a tempered glass on the top. Placed between the solar cells and the glass there is a thin usualy EVA foil. Solar cells are interconnected with thin contacts on the upper side of the semiconductor material, which can be seen as a metal net on the solar cells. The net must be as thin as possible allowing a disturbance free incidence photon stream. Usually a module is framed with an aluminium frame, occasionally with a stainless steel or with a plastic frame. Special flexible modules are designed for use on boats that can be walked upon without causing any damage to the modules. The typical crystalline modules power ranges from several W to up to 200 W/module. Some producers produce preassembled panels with several 100 Wp. Over its estimated life a photovoltaic module will produce much more electricity then used in it's production and a 100 W module will prevent the emission of over two tones of CO2.

Module Construction

Photovoltaic module consists of transparent front side, encapsulated solar cells and backside. As front side material (superstrate) usualy low-iron, tempered glass is used. For some special module types some other front side materials are used like polycarbonate or non-tempered glass for example. For flexible modules ethylene tetrafluoroethylene (ETFE) a fluorine based plastic, with high corrosion resistance and strength over a wide temperature range.is often used. Backside is usualy non transparent, most common used material is polyvinyl fluoride (PVF). Transparent back side is also possible - transparent back side materials are often used in modules that are integrated into buildings envelope (facade or roof), see also BIPV section. Between glass and back side solar cells encapsulated with encapsulation material are placed. Many different materials can be used for encapsulation but two most often used materials are EVA (ethylene-vinyl-acetate) and PVB (polyvinyl-butiral). PVB is also used in safety windscreens in automotive industry. It is used as encapsulation material in transparent modules. EVA is used for encapsulation of cells in standard modules. Other less common encapsulation materials are thermoplastic polyurethane (TPU) and polyurethane or silicone cast resins used for example in transparent modules or other demanding applications. Required mechanical characteristics (impact resistance etc.) and module qualification procedures are defined in international standards, for details please see standards section.

General electrical and mechanical properties

The most important module parameters include a short circuit current, an open circuit voltage and a nominal voltage at 1000 W/m2 solar radiation, current and rated power at 1000 W/m2 solar radiation value. Module parameters are measured at standard test conditions (STC) - solar radiation 1000 W/m2, air mass (AM) 1,5 and temperature 25"deg;C. The following parameters can usualy be found in module datasheets:

| Peak power | PSTC | Wp |

| Open cirquit voltage | Voc | V |

| Short cirquit current | Isc | A |

| Voltage at maximum power | VMPP | V |

| Current at maximum power | IMPP | A |

| Beam irradiation | Hb | J/m2 |

| Maximum system voltage | Vmax | V |

TABLE 1: Electrical parameters of photovoltaic (solar) modules

TABLE 2: Non-electrical parameters of photovoltaic (solar) modules

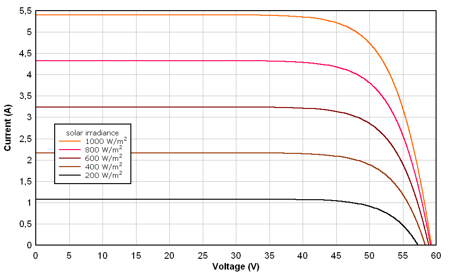

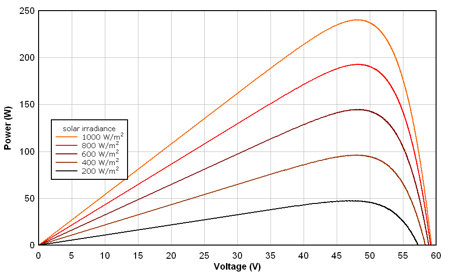

Samples of solar modules I-V and power characteristics are presented on pictures

below. Presented characteristics were calculated

for solar module with following data: Voc = 48,1 mV,

Isc = 5,8 A,

IMPP = 4,99 A,

VMPP = 59,3 V,

and PMPP temperature coefficient γ = -0,0045 %/K.

Calculation algorithm presented in the book Photovoltaik Engineering (Wagner, see sources) was used.

Example of solar module I-V characteristics for different irradiation values

Example of solar module power characteristics for different irradiation values

Commercial crystalline photovoltaic modules efficiency typically ranges from

12 to 15 %. However, you must be aware, that the solar cell efficiency doesn’t

equal the module efficiency. The module efficiency is usually 1 to 3 % lower than

the solar cell efficiency due to glass reflection, frame shadowing, higher

temperatures etc. Amorphous modules have the lowest price, yet their lifetime is

shorter and their efficiency is up to 10 % only.

All electrical parameters of solar module depends on temperature.

Values are important in design stage of PV system and they should be considered

as important parameters related to the PV system design.

The most common

temperature coefficients that are usualy available in module data sheets are

presented in table below - values are valid for crystalline Si solar

modules only:

TABLE 3: Temperature coefficients of electrical parameters for Si-crystalline cells/modules

Front and back side of crystalline Si flexible solar modules are most

often produced from plastic materials like

poly(methyl methacrylate) (PMMA) or polycarbonate.

For demanding applications transparent flexible modules can be produced.

Amorphous Si flexible modules are also available. As modul substrate

EPDM (ethylene propylene diene Monomer/M-class) synthetic rubber is used.

This material can also be used in combination with bitumen what makes it a

preffered choice for flat roofs.

Krinner

- Ground screws for photovoltaic systems.

DOMA-Drehfundamente

- Ground screws for photovoltaic systems.

Schletter

- photovoltaic array mounting structures for wide variety of applications.

Unirac

- UniRac manufactures photovoltaic mounting structures for any type of solar

installation.

Professional Solar Products

- ProSolar has been manufacturing solar equipment longer than any other PV mounting manufacturer.

DPW Solar

- we provide innovative mounting solutions for any PV solar application including commercial, industrial, government, utility and residential applications.

IronRidge

- IronRidge solar mounts are relied upon every day in solar PV installations that range from small, single-use residential solar applications to some of the largest industrial solar deployments in the world.

Pole mounted array structure, Solarpark Waldpolenz, Germany during construction

SOLAR FASTENER EXPERT

- SOLAR FASTENER EXPERT.COM was created to provide a site where Installers,

Integrators, Manufacturers and Maintenance contractors could easily obtain all

the Stainless Steel Fasteners needed in their projects at a single source.

Heyco

- Founded in 1926 and still family owned. Heyco Products Inc. offers decades

of experience in the design and manufacture of molded wire protection products

and stamped electrical components to meet demanding customer application

requirements.

Schäfer + Peters

- Schäfer + Peters is your partner for stainless steel and anti-corrosion

fasteners, DIN and standard parts such as wood screws, metric screws, tapping

screws, washers, nuts and also products such as heavy-duty fastenings, safety

screws and solar fastenings as well as special and drawing parts.

HECO Schrauben

- HECO-TOPIX®-T Solar made from stainless steel

is the ideal fixing solution for solar panels on

over-rafter-insulated roofs.

Nominal operating cell temperature

NOCT

°C

Open cirquit voltage

Voc

V

Storage temperature

Tstor

°C

Wind loading of surface pressure

Cp

N/m2 (km/h)

Impact resistance

-

mm at km/h

Module efficiency

Temperature coefficients

Short cirquit current

α

from +0.03%/K to +0.1%/K

Open cirquit voltage

β

from -0.33%/K to -0.40%/K

Maximum power (MPP)

γ

from -0.40%/K to -0.50%/K

Flexible Modules

Ground screws

Mounting structures

(credit: pvresources)

Screws and fastening

Books

![]()

Poliskie, M. (2011), Solar Module Packaging: Polymeric Requirements and Selection;

CRC Press, ISBN 978-1439850725.

![]()

Tiwari, G.N., Dubey, S. (2009), Fundamentals of Photovoltaic Modules and their Applications;

Royal Society of Chemistry, ISBN 978-1849730204.

![]()

Wagner, A. (2006), Photovoltaic Engineering, Handbuch für Planung, Entwicklung und Anwendung;

Springer, ISBN 978-3-540-30732-7.